Laminar Air Flow

A laminar air flow workstation comprises of a chamber fitted with HEPA filter and centrifugal blower assembly. It is widely used in microbiological manipulations, sterile testing and some work with sub-toxic materials etc.

Our standard models of Laminar Air Flow are made with high quality HEPA filters (0.3 microns) and offer class 100 cleanliness level. These benches are made in both Vertical and Horizontal designs as required by our customers. Standard units are made with powder coated MS sheets but we also use stainless steel 304 in needed. Worktop is made of SS 304 and side panels are made of glass or steel sheets.

They are also known as laminar flow cabinet.

In laminar flow cabinet air flows through the cabinet.

It works by the use of inward flow of air through one or more HEPA filter to create bacteria free environment.

Laminar air flow create dust free air environment.

Air from room passes through HEPA filter & is fed into working chamber.

Laminar Air Flow Manufacturer

iLabot brings to you cost effective range of laminar air flow chambers in both vertical and horizontal designs. We have been making laminar air flows for over 25 years and each unit have been acclaimed by industry experts for their design, construction and efficiency. It is our technical knowhow, years of experience and feedback of existing customers that we have managed a good reputation in the field of laminar flow workstations in India.

A magnehelic gauge is fitted at front panel to show the pressure. Other standard accessories are UV light, LED light and centrifugal blower. Door is made of acrylic sheet which is vertical sliding type. These LAF workstations are made in different sizes such as 2 ft, 3 ft, 4 ft and 6ft or customized as required.

Technical Specifications |

||||

| Sizes (Ft.) | 2 x 2 x 2 | 3 x 2 x 2 | 4 x 2 x 2 | 6 x 2 x 2 |

| Air Flow | Vertical and Horizontal | |||

| Cleanliness | Class 100 | |||

| Particle retention | 0.3 micron | |||

| Velocity | 90 FPM | |||

| Illumination | 700 – 800 lumen | |||

| Noise level | 60-65 decibels | |||

| Construction | Powder coated MS / SS 304 | |||

| Door | Transparent door vertical sliding | |||

| Worktop | SS 304 | |||

| Power supply | 220 Volts 50Hz | |||

| Optional |

|

|||

Contruction & Features

> Lower Cost.

> Superior build quality to reduce noise.

> User Friendly Ergonomic Design.

> Controlled Environment Particulate Free Product Protection.

> Basic material is thick board wood front back top and exterior surfaces are covered with Formica. OR Cold rolled steel duly powder coated OR Stainless Steel (SS-304) (as ordered).

> Working table is made of Stainless Steel Sheet (SS-304 grade).

> All interior surfaces are epoxy painted filter seat is carefully formed, installed and checked for leakage.

> Side panels & front doors are made of 6 mm thick acrylic transparent plexi glass.

> The highly efficient HEPA filter with pre-filter maintains the optimum cleanliness and purity.

> Working area is illuminated by fluroescent lighting fitted to the unit.

> The blower and motor assembly is statically and dynamically balanced of 1/5 H.P. capacity operates with minimum noise level.

> Height of the working table provides comfortable "SIT DOWN" working position for the operator.

Applications of Laminar Air Flow

Both the vertical and horizontal laminars have application for Culture analysis, Bacteriological & Biological applications in Hospitals, Plant Tissue Culture, Labs, Food, Beverage and Electronic industries. It provides an economical work environment- suitable for hospitals, drugstore, pharmaceuticals factories, sanitation and anti-epidemic stations.

Types of Laminar Air Flow

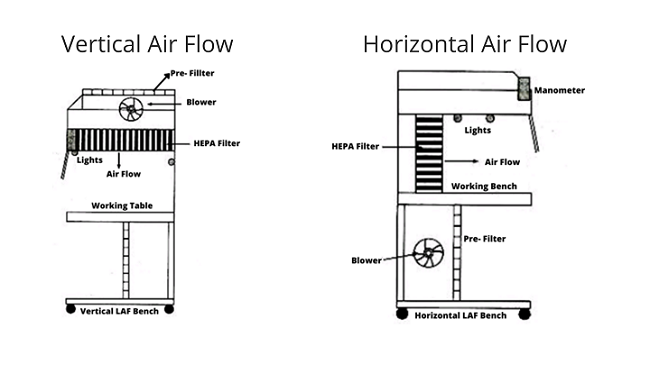

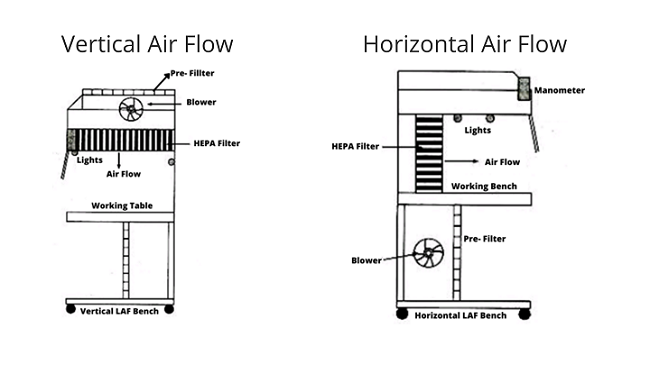

Vertical Laminar Air Flow

In vertical Laminar Air Flow the Pre-filter and the Blower is mounted on the top of the cabinet. HEPA filter is also located on the top of the working area. Air flow vertically downward on the working area. It provides greater operator protection.As we can see in the picture the Atmospheric Air entering in pre- Filter and gets filtered then entered in HEPA Filter through the blower, HEPA make the air more efficient (99.97 % particles 0.3 µm micron) then air comes in the chamber of the Laminar Air Flow through the HEPA Filter.

Horizontal Laminar Air Flow

In Horizontal Laminar Air Flow the Pre-filter and the Blower is mounted on the Bottom of the cabinet. HEPA filter is located in the front of the Operator as seen in the picture of Horizontal LAF Cabinet. HEPA Filter Filtered air and exhaust to the front of the working area. As we can see in the picture the Atmospheric Air entering in pre- Filter and gets filtered then entered in HEPA Filter through the blower, HEPA make the air more efficient (99.97 % particles 0.3 µm micron) then air comes in the chamber of the Laminar Air Flow through the HEPA Filter.Main Parts of Laminar Air flow

HEPA Filter: HEPA is stand for High Efficiency Particulate Air) Filter, HEPA Filter is made up of borosilicate microfiber in the form of plated sheet. It removes 99.97 % of particles ≥ 0.3 µm micron.Pre- Filter: Air 1st comes in Pre- Filter in Laminar Air Flow, It Provide 40 % of efficiency.

UV Light: Germicidal UV light is uses in Laminar Air Flow. It is on the top side of Laminar Air Flow. UV lights can be very effective at killing viruses, mold, and bacteria. It should be switched OFF while working on the working table because it causes skin cancer.

Florescent Lamp: It is a lamp for the visibility on the work bench.

Blower: A blower circulates the air only on the specific point like HEPA Filter and the HEPA filter provide the clean and dust free air to the Laminar Air cabinet.

How to use Laminar Air Flow

• 1st Switch ON the power supply.• Then turn on the UV lamp for 10 to 15 minutes.

• Then switch OFF the UV lamp and turn on the blower. Now blower flow air to the HEPA Filter.

• Also turn on the florescent lamp for the visibility on the working table.

• HEPA clean the air more efficient (99.97 % particles 0.3 µm micron) for the chamber of the Laminar Air Flow.

• Now adjust the door according to the comfort ability of the person who is work on the cabinet.

• After the completion of work on the cabinet switched OFF the main supply of the Laminar Air Flow.

Precautions

• Before starting work clean the cabinet from the sanitizer to clean the surface of the cabinet.

• Do not speak during working on the cabinet because if we speak many small particles, can enter in the cabinet which cannot be seen with our naked eyes.

• Do not work on the working bench when the UV Lamp is switched ON because it causes Skin Cancer. Switched OFF the UV Lamp before starting work on the working bench.

• Clean the filters time to time for long life of the cabinet.

CONTACT

Related Cleanroom Products

> Laboratory Fumehood

> Biosafety Cabinet

> Pass Box

> Air Shower

> Sanitization Chamber